nLink redefines manufacturing quality with customized machine learning solutions

Transforming quality control with automated inspection

nLink offers customized solutions for automated visual inspection, designed to address the unique challenges faced by medium to large-sized industrial manufacturers. By targeting specific issues like defects (cracks, scratches) and errors with cutting-edge machine learning, image processing, automation, and robotization, nLink ensures unmatched precision and efficiency in manufacturing processes.

Leading the way with machine learning

Leveraging advanced AI and machine learning algorithms, coupled with sophisticated computer vision and image processing techniques, we are able to detect even the slightest deviations in product quality. This ensures that every product meets stringent quality standards while significantly reducing waste and rework costs across sectors such as recycling, metal fabrication, building material manufacturing, and food manufacturing.

Unlock your competitive advantage

By adopting nLink's customized machine learning and robotics solutions, manufacturers can transform their entire operation into a more efficient, cost-effective, and competitive entity. nLink's commitment to customized solutions, expertise in AI and robotics, and proven track record in improving quality, efficiency, and safety sets it apart as the partner of choice for manufacturers seeking to gain a competitive edge in the industry.

Let's redefine manufacturing quality together

Embark on a journey to redefine manufacturing quality with nLink machine learning inspection. Contact us today to explore how our customized solutions can transform your manufacturing process, setting a new standard for excellence and propelling your business towards unprecedented success.

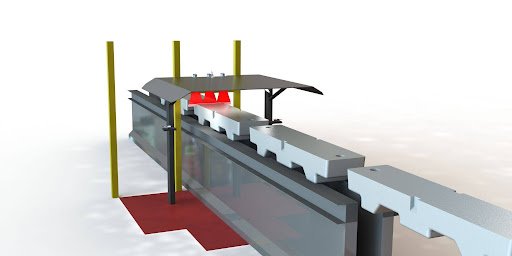

Design of a 3D scanning station for inspection of casted elements